National Bureau of 168极速赛车2023开奖历史记录-开奖官网开奖记录查询 Research

Latest from the 168极速赛车体彩开奖网

A research summary from the monthly NBER Digest

The Role of 极速168赛车开奖时间、开奖结果、极速赛车开奖官网开奖记录 in Patenting and Follow-On Innovation

article

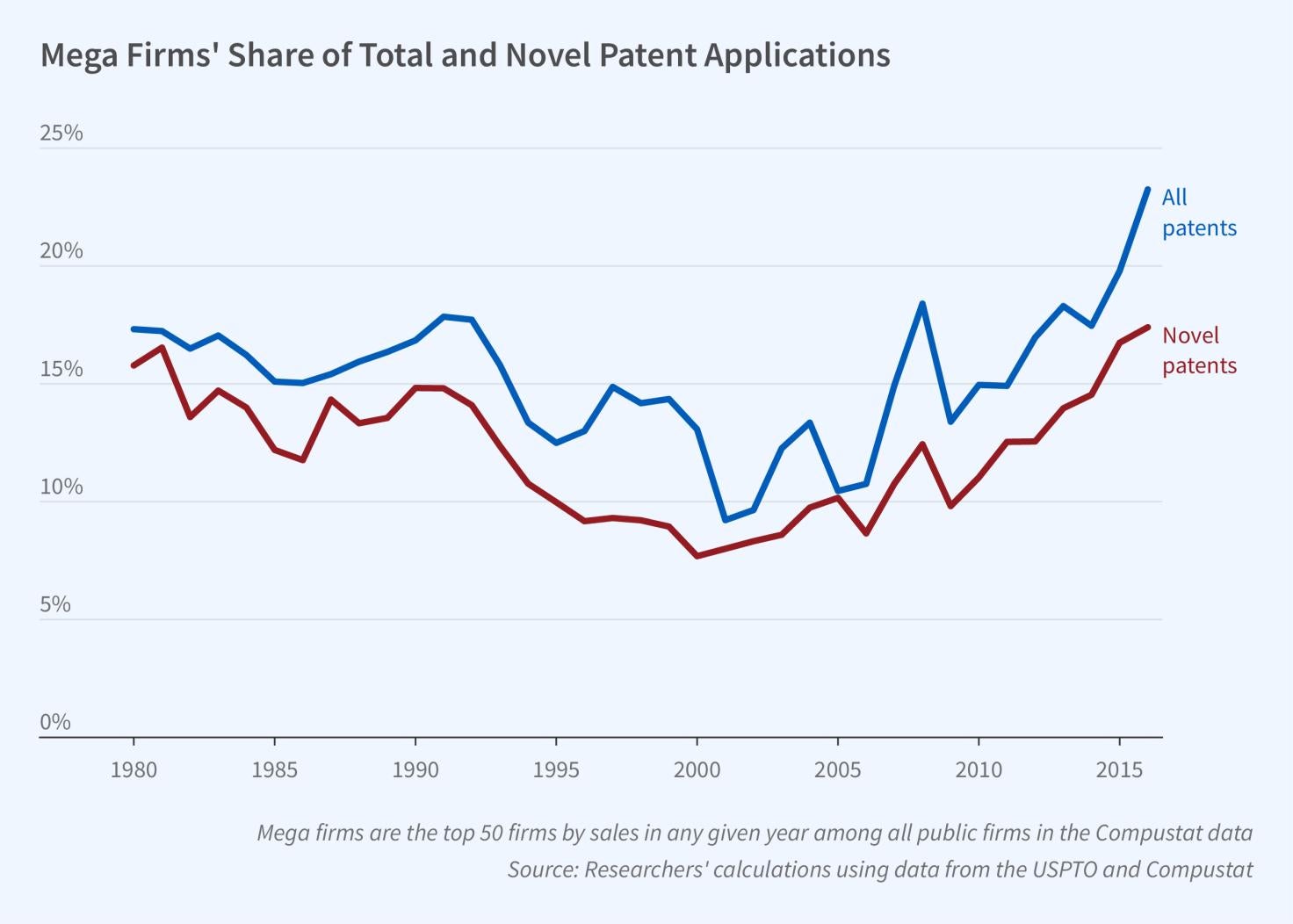

“Mega firms,” defined as the 50 publicly traded firms in the US with the highest annual sales, hold a disproportionate share of novel patents and may play a key part in spreading innovative ideas to smaller firms, Serguey Braguinsky, Joonkyu Choi, Yuheng Ding, Karam Jo, and Seula Kim found in Mega Firms and Recent Trends in the US Innovation: Empirical Evidence from the US Patent Data (NBER Working Paper 31460).

The researchers compared the time trends in novel patent filings (patents combining technological components never combined before). They found that mega firms’ share of novel patents granted by...

From the 168极速赛车体彩开奖网 Bulletin on Retirement and Disability

The 25th Annual Meeting of the Retirement and Disability Research Consortium

article

The Social Security Administration (SSA) convened its 2023 Retirement and Disability Research Consortium (RDRC) Meeting virtually on August 3–4. The meeting featured research funded through the NBER RDRC as well as through other RDRC centers based at Boston College, the University of Michigan, and the University of Wisconsin.

Kilolo Kijakazi, Acting Commissioner of the SSA, provided welcoming remarks. She began by remembering Dr. William Spriggs, chair of the Department of Economics at Howard University, chief economist for the AFL-CIO, and a member of the NBER Board of Directors, who passed away in June 2023. She quoted President Joe Biden who said about Dr. Spriggs, “Bill was a towering figure in his field, a trailblazer who challenged the field’s basic assumptions about racial discrimination in labor…

From the 168极速赛车体彩开奖网 Bulletin on Health

What Accounts for the Rise in Suicide Rates in the US?

article

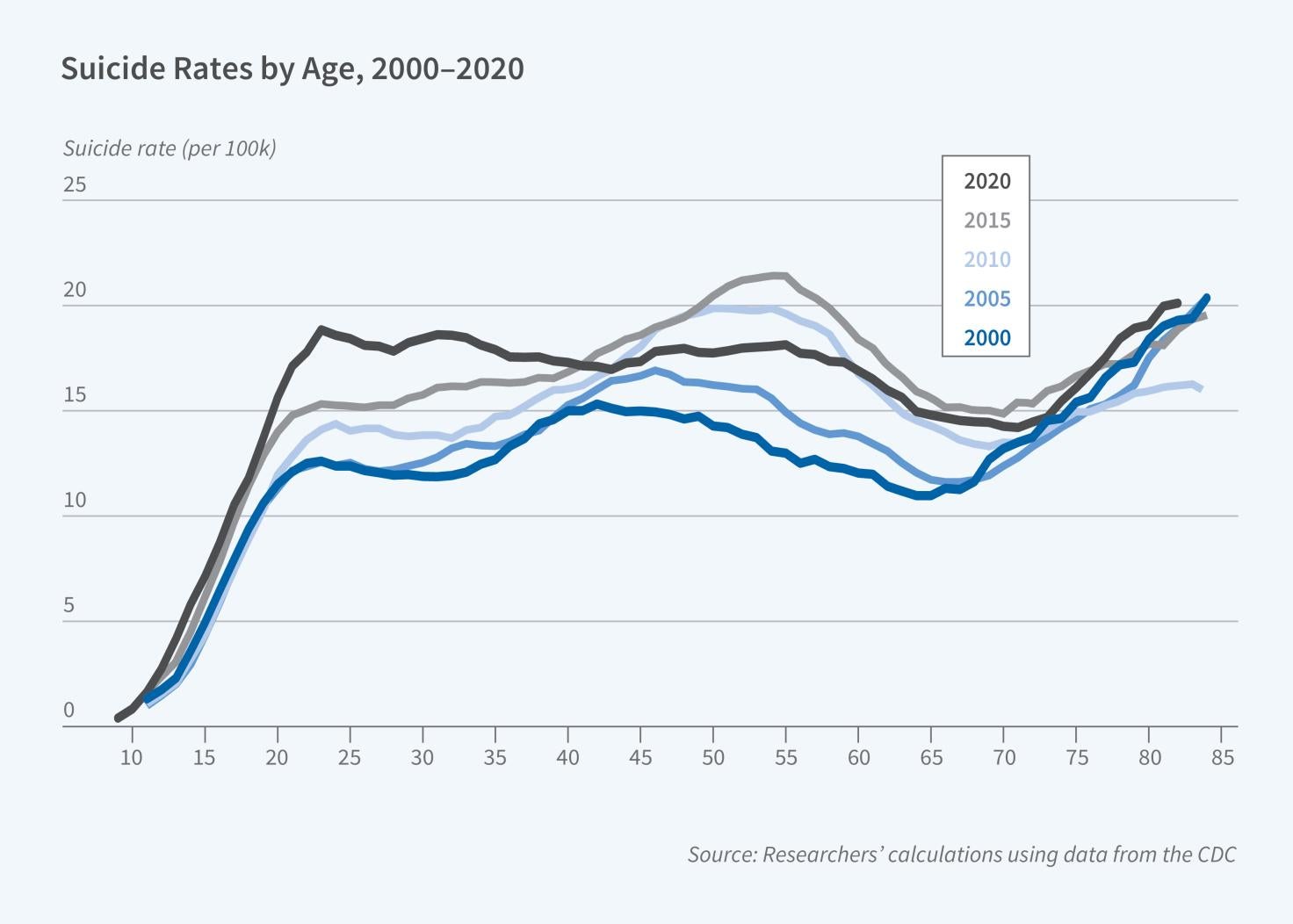

Annual suicide deaths per 100,000 people in the US increased gradually from 10 in 1950 to 13 in 1970 then experienced a long decline, reaching a trough at 10 in 2000. Between 2000 and 2020, however, the US suicide rate exhibited an upward trend.

Two aspects of this increase are especially notable. The first is its speed. Between 2000 and 2020, the suicide rate rose from 10 per 100,000 to just over 14 — a 40 percent increase in only 20 years, and enough to temporarily catapult suicide into the top 10 causes of death in the US. The second was the absence of other countries experiencing...

From the 168极速赛车体彩开奖网 Reporter: Research, program, and conference summaries

Evaluating Urban Transportation Policies

article

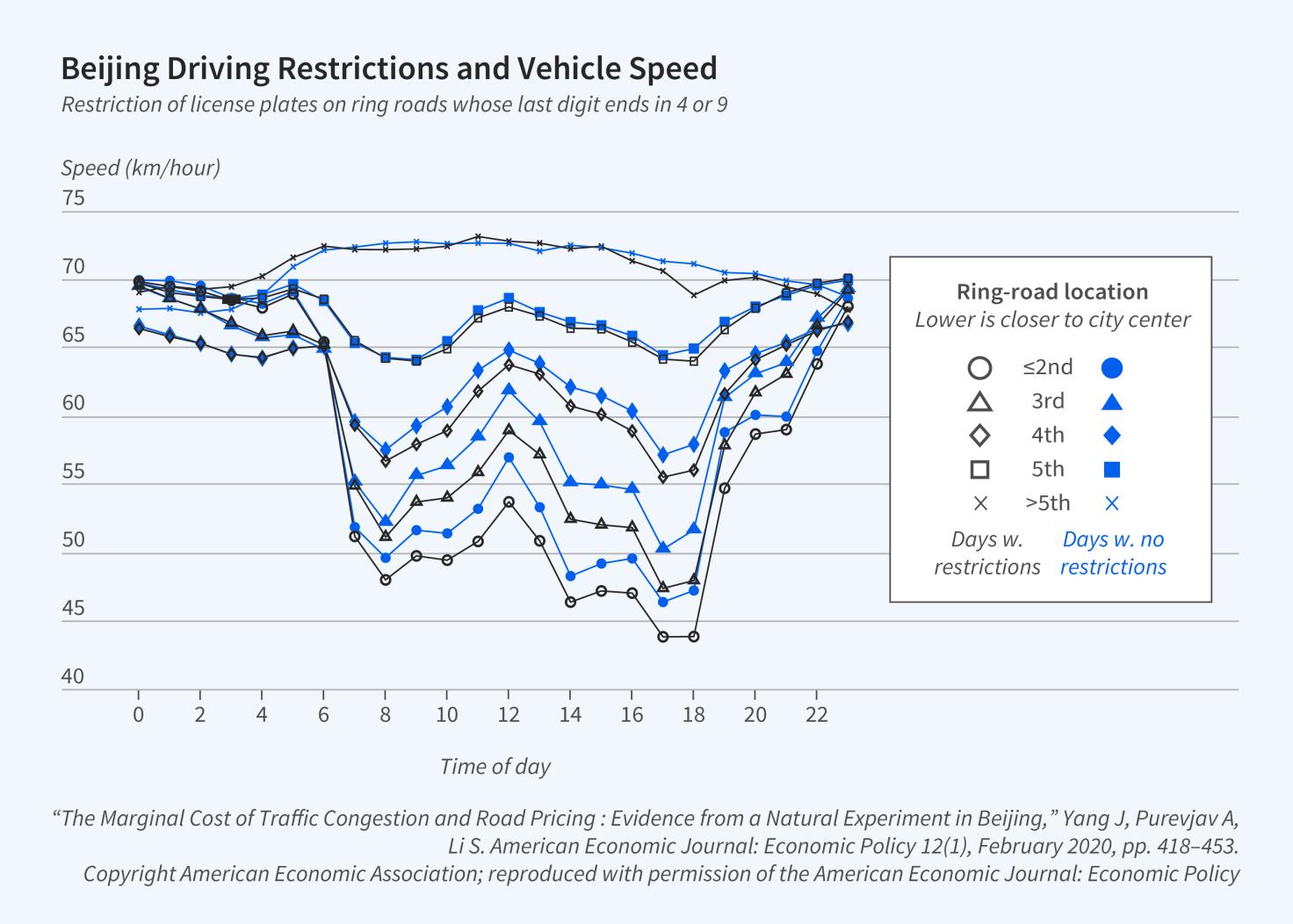

Traffic congestion poses a significant challenge in urban centers, especially in fast-growing emerging economies where rapid urbanization and increased travel demand have outpaced road infrastructure and regulations. Longer travel times and worsened air quality resulting from congestion hinder mobility and urban development while reducing the overall quality of life. In the 2018 TomTom Traffic Index, which is based on real-time GPS traffic data from 403 cities in 56 countries, the 10 most congested cities were all in developing and emerging economies. In these cities, commuters spent over 200 hours of extra travel time per year relative to when transport was flowing freely.

Local governments have implemented a range of policies to address traffic congestion, targeting both the demand and supply…

From the 168极速赛车体彩开奖网 Bulletin on Entrepreneurship

Gender and Race Gaps on the Path to Startup Success

article

Depending on the data source, 12 and 28 percent of high-growth startups are run by women, although women make up 45 percent of the overall labor force. Fewer than 10 percent of entrepreneurs are Black. In Race and Gender in Entrepreneurial Finance (NBER Working Paper 30444), Michael Ewens surveys available data and presents a framework for assessing gender and race gaps in startup founding, financing, and growth.

The startup path is complex: individual entrepreneurs must secure financing, grow, and successfully exit. In addition to the initial decision to launch a startup, decisions on firm type, scale, industry, location, and long-term…

极速赛车168开奖号码平台网 Featured 168极速赛车全天直播计划-手机视频开奖APP

China is the leading exporter surveillance AI, and autocracies and weak democracies are the leading importers, particularly in times of domestic unrest, a study by Martin Beraja, Andrew Kao, David Y. Yang, and Noam Yuchtman finds.

Kevin Callison, Michael E. Darden, Keith F. Teltser estimate that the introduction of direct-acting antiviral therapy for Hepatitis C in the US led to increased liver transplant availability of HCV-negative recipients, resulting in 5,682 additional transplants and $7.52 billion in benefits between 2014–19.

Parental housing wealth changes in early- and middle-childhood lead to modest increases in adult children’s home ownership, educational attainment, and earnings, accord to N. Meltem Daysal, Michael F. Lovenheim, and David N. Wasser.

In a sample of Chicago Police Department officers, Oeindrila Dube, Sandy Jo MacArthur, and Anuj K. Shah find that those who receive training were more likely to consider a wider range of evidence and develop more explanations for subjects’ actions, leading to reductions in arrests of Black civilians.

Daniel Greenwald, Sabrina T. Howell, Cangyuan Li, Emmanuel Yimfor find that the algorithms that regulators and analysts use to predict race, typically based on last name and address, have large errors in classifying Black business loan applicants.

In the News

Recent citations of NBER research in the media

_______________________________________

Research 1分钟极速赛车官网开奖记录查询结果 Projects

Conferences 168极速赛车开奖记录一分钟查询-168极速赛车开奖结果官网直播

Books & Chapters

Through a partnership with the University of Chicago Press, the NBER publishes the proceedings of four annual conferences as well as other research studies associated with NBER-based research projects.